Engineered Control Valves for Custom Aerospace Testing Systems

Ground testing of turbines, rocket engines, fuel systems and components is critical to ensure flight worthiness.

Engineers for these systems and components require valid data to thoroughly understand the operation of the system or individual component under an array of environmental conditions.

Trimteck engineers control valves to tackle the most challenging process conditions in the industry. We manufacture a suite of flow, temperature, and pressure control solutions for aerospace applications that includes the OpGL-XT – a rugged, multi-purpose, custom-engineered globe control valve for applications ranging from extreme differential pressures to cryogenic temperatures.

Recent Applications

Application: Rocket Propulsion System Testing –Bubble-tight Shutoff of Liquid Oxygen in Chemical Steam Generator

Location: Mississippi, USA

Requirements: A cage-less cryogenic globe valve for quick, safe, and repeatable Class VI shutoff of LOX in a new CSG system used to create a vacuum chamber for rocket component testing.

Solution: In close collaboration with the customer, Trimteck designed and manufactured QTY27 custom 2” CL300 OpGL-XTSB Cryogenic Angle/Split Body valves fitted with OpTK piston-cylinder actuators. The rugged split body configuration allowed for the seat to be held in place without the need for a retainer or a cage. The force applied by six equidistant bolts holding the upper and lower body segments together ensures that the seat is “sandwiched,” subjected to even pressure, and held in place to reduce the effects of line torsion or vibration on the seal. Tight shutoff was achieved using our standard soft wafer seat insert that is easily and inexpensively replaceable when servicing the valve.

Application: High Pressure Letdown of Gaseous Nitrogen

Location: Louisiana, USA

Requirements: Forged-body angle-valve with noise abatement severe service trim and a custom face-to-face to replace an existing legacy valve at this aerospace testing facility

Solution: Working closely with the customer, Trimteck designed a 2″ CL1500 OpGL-XT withST-3 multi stage noise abatement trim. The valve was not only built to fit perfectly in the space left by the valve we replaced, but it was a significant upgrade in the way of noise abatement trim, materials used, and controllability.

Application: Cryogenics Lab – Flow and Pressure Control

Location: Florida, USA

Requirements: Replacements for obsolete Domotor Actuators on legacy Annin Valves manufactured in the 1960s

Solution: Trimteck designed retrofit kits to install our OpTK Piston Cylinder Actuators with HPP4000 Smart Valve Positioners on the existing Annin valves. In doing so, we were able to significantly extend the useful life of these critical cryogenic valves at Kennedy Space Center.

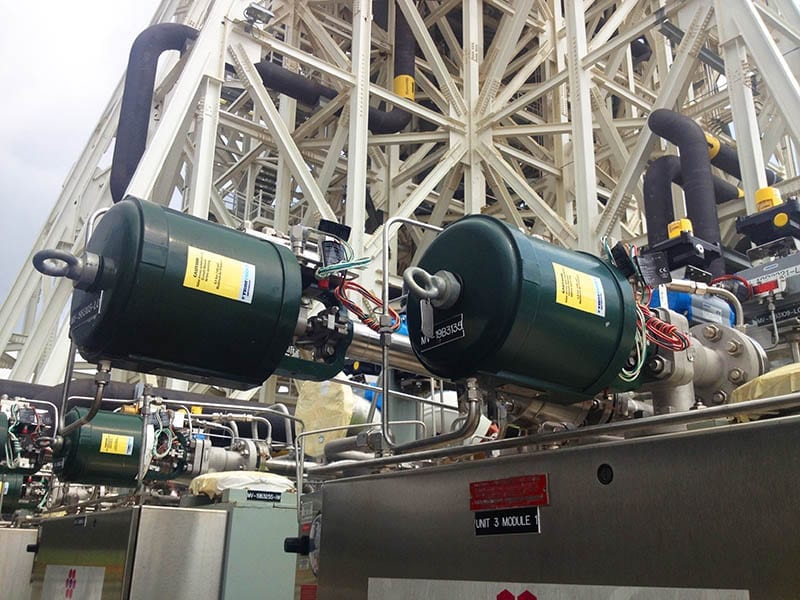

Application: Turbofan Engine Component Testing – Controlling Compressor Exhaust System

Location: Massachusetts, USA

Requirements: A series of compact, versatile, and re-usable globe control valves for bleeding compressors on a Small Engine Compression Testing system. 19 distinct applications were provided, each with various process conditions – depending on what test the customer would be running – and the customer wanted to maximize interchangeability of the equipment without sacrificing performance.

Solution: Trimteck devised a solution using our standard, rugged, stem-guided Optimux OpGL Globe Control Valves ranging in size from ½” to 6” and CL150 to CL600, in which we minimized the number of valves purchased by the customer to 12, so that at least seven (7) of the units could be easily re-used for multiple test configurations.