Top 3 control valve sizing and selection best practices for engineers

When choosing a control valve, “off-the-shelf” products won’t always meet your stringent requirements. This is especially true in severe service applications, where a control valve must withstand extreme temperatures, corrosive materials, or complex flow conditions. Failing to do so may result in premature failures and — as a result — costly downtime.

To avoid this fate and ensure your application runs smoothly, you need to select and size the right *custom* control valve.

In this blog, we’ll walk you through three best practices for control valve sizing and selection to help you choose the right control valve for your process.

1. Situation: Why do you need a new control valve?

Step one is to place your project into one of three categories:

- New construction — you need to design and build a new process that requires a control valve. Here, calculated process conditions, vetted by a series of stakeholders, will guide your sizing and selection decision.

- Upgrade (MRO) — you need to replace an existing control valve at an existing site. Here, the more information you can gather about the existing control valve and its use case, the better. We’d recommend making a note of: manufacturer, model/trim, materials, end connections, process frequency, and length of service.

- Spare parts — you need to service or replace components in an existing valve. Again, the more information you can obtain about the existing control valve, the more informed your decision will be. This ensures like-for-like (or improved) part replacements.

Once you categorize your project, you can budget your costs and time expectations effectively.

Naturally, new construction will require a larger budget and a longer project timeline. Upgrades and spare parts may have a shorter timeline and lower costs, but this is dependent on the complexity of your application and use case.

2. Selection criteria: What is your control valve for?

Now that you’ve determined your situation, it’s time to dig deeper into your specification requirements. This will help you select the right control valve for your application.

To help you, we’ve categorized these considerations and posed some important questions:

- Operating conditions:

- Is it a modulating or control application?

- Is it two-way or three-way (mixing or diverting)?

- Is it a single valve or a staged requirement?

- The piping detail - is it horizontal?

- What is the pipe material?

- What is the Inlet pressure (P1) and Outlet pressure (P2)?

- What is the temperature?

- Are there Pressure codes or hazardous restrictions in place?

- Fluid properties:

- Does it handle hot or cold water, chemical additives, or an undefined liquid?

- Does it handle gas?

- Does it handle steam? At what temperature (saturated or superheated)?

- Is the fluid clean, single-phase, corrosive, abrasive, or flammable?

- If slurry, what is the concentration?

- Flowing conditions:

- What are the pounds per hour (Lb.hr), gallons per minute (GPM), and other measurements during normal and start-up conditions?

- What is the required rangeability or turndown ratio?

- Is leakage allowed?

- Is the system OFF for extended periods?

- Sizing methods:

- Have your process conditions been verified? Or are you taking an educated guess?

- Where is the installation taking place - is it occupied or elevated?

- Will surrounding activities such as moving vehicles impact installation?

- Are fire safety policies in effect?

- Function:

- Is a failsafe mode required? Do you need a manual override?

- What are your preferred end connections? Flanged? Threaded? Welded?

- Are the trim and packing choices supported by engineering considerations?

- What actuation do you need - pneumatic or electric?

- Are accessories required (positioner, air set, and thermal/acoustic insulating blanket)?

- Miscellaneous:

- In an MRO situation, do you have the original valve’s paperwork and warranty information?

- Where will you store the new documentation?

- What is the control source (PLC, DCS, PID, other)?

By answering the list of questions above, you’ll have a better idea of the type of control valve you will need for your application.

3. Sizing: What is the optimal valve size and style to control your process?

Finally, you’ll want to correctly size your control valve by assessing your expected process condition. These include the function of the valve, the severity of the service, and the required flow.

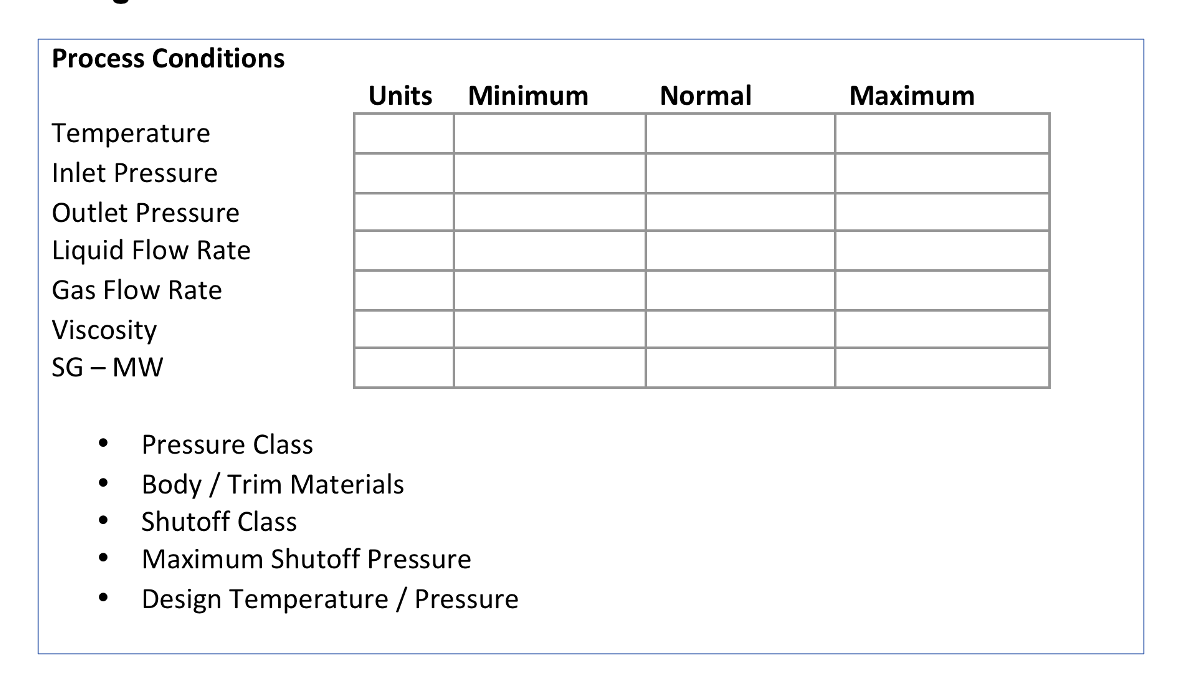

To get this right, identify the units, minimum, normal, and maximum conditions for:

- Temperature

- Inlet pressure

- Outlet pressure

- Liquid flow rate

- Gas flow rate

- Viscosity

- Specific gravity (SG) - molecular weight (MW)

During this process, it can be helpful to create a table of your requirements. Here’s one we share with our clients:

Next steps: choose the right control valve

Your control valves need to stand up to extreme conditions and we want to help you choose the right product to ensure operational efficiency, safety, and environmental compliance.

At Trimteck, we manufacture control valves for the world's most critical applications. We work closely with engineers to manufacture high-quality control valves that fit their custom specifications and provide superior performance.

To talk to us about your control valve needs, please get in touch with our sales engineering team.